The Rise of the X-ray Film Digitizer

As technology evolves, the X-ray Industrial film digitizer has emerged as a revolutionary tool. Such advancements simplify tasks that were previously labor-intensive, accelerating progress in fields like healthcare and industrial testing. Thanks to its high-resolution imaging, the digitizer has fundamentally transformed Non-Destructive Testing (NDT) / Radiographic Testing (RT) industry.

Traditionally, radiography relied heavily on physical film processing. However, the introduction of the X-ray film digitizer has paved the way for digital solutions. Today, professionals can quickly scan films, producing digital images that can be effortlessly stored, shared, and analyzed.

In the wake of this technological shift, the benefits are immense. Digitization reduces storage space, enhances image quality, and streamlines operations. Undoubtedly, the X-ray film digitizer is catalyzing a new era in radiographic testing.

Why Choose the NDT-2000 Film Digitizer?

If you’re involved in radiographic testing, investing in an X-ray film digitizer is a game-changer. It accelerates scanning processes, providing precise digital records. Moreover, with modern digitizers, such as Microtek NDT-2000 Film Digitizing System, you can manage a larger volume of films with greater accuracy.

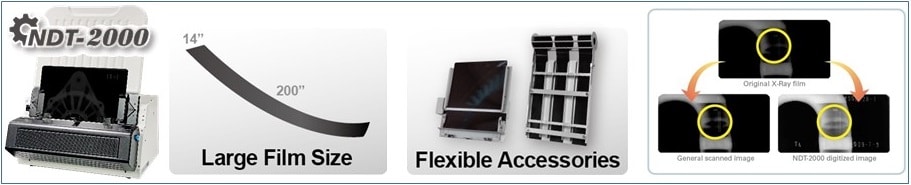

Another compelling reason to choose the NDT-2000 digitizer is its ability to handle various film sizes. For instance, industrial digitizers can manage films as large as 14″ x 200″. Thus, regardless of your requirements, the X-ray film digitizer can accommodate your needs.

Finally, the introduction of specialized software with digitizers has revolutionized the sector. Microtek’s ScanWizard NDT & MiiNDT softwares allows users to manipulate digital images, perform measurements, and create detailed reports. Hence, an X-ray film digitizer isn’t just a scanning device; it’s a complete radiographic testing solution.

Unpacking the Features of an X-ray Film Digitizer

When selecting an X-ray film digitizer, you should consider its features carefully. High-resolution scanning capabilities are paramount. Digitizers offering up to 1200 dpi resolution ensure clarity and detail in your scanned images in 3.5D, 4.0D and 4.5D modes with Dynamic Range between 0.37 and 4.5.

Another feature to look out for is a user-friendly interface. This ensures a smooth experience when operating the digitizer. Coupled with robust software, the digitizer should support a variety of image output formats like DCM, BMP, JPEG, and TIF.

Lastly, consider the additional features offered by the digitizer. These may include multi-channel trays or automatic film feeders (AFF), which enhance the efficiency of the digitizing process. Thus, the X-ray film digitizer you choose should be well-equipped to handle your radiographic needs.

1. Understanding the Concept of Radiographic Testing

Radiographic Testing (RT), often referred to as X-ray or Gamma ray testing, is a revolutionary non-destructive testing method. It allows you to investigate the interior of a specimen without causing any harm or alteration. By using X-rays and gamma rays, RT generates an insightful radiograph of the specimen.

This radiograph, in turn, reveals vital information such as variations in thickness, internal and external defects, and assembly details. It is like having x-ray vision, enabling you to see the very core of the material under examination. With RT, you’re empowered to ensure the utmost quality in your operations.

Over the years, the RT method has found broad application across industries. It’s predominantly used in manufacturing, construction, aerospace, and other sectors where internal quality assurance is of high importance. It’s clear that RT has drastically changed the game for industrial inspection and quality control.

2. The Power of Non-Destructive Testing in RT

RT’s primary strength lies in its ability to penetrate a wide range of materials with varying densities. The unique ability of RT allows it to detect internal defects in weld quality, a crucial aspect in many industries. Furthermore, it can profile in-service systems to ascertain if corrosion or erosion is present.

Additionally, RT is instrumental in assessing castings for fabrication flaws or foreign objects. These evaluations can be crucial in maintaining the integrity and safety of critical structures and systems. Lastly, RT can detect damage in composites, further expanding its utility in various industries.

The benefits of RT extend beyond just defect detection. It helps organizations make informed decisions about system maintenance and component replacement. The overall result is improved safety, cost savings, and extended equipment life.

Introducing the Microtek NDT-2000 Film Digitizing System

3. Enter the NDT-2000 X-ray Film Digitizer

Microtek, a leader in digitization solutions, introduces the NDT-2000 X-ray Film Digitizer specifically designed for the Non-Destructive Testing (NDT) industry. This state-of-the-art tool transforms traditional radiographic films into digital files. It is a seamless transition into digital management for businesses engaged in the NDT/RT industry.

The NDT-2000 isn’t just a mere upgrade from its predecessor, but a significant leap forward. It brings about better industrial digitizing images, which can make a world of difference in inspections. When used with MiiNDT, an image analyzation and management software, it enables more effective solutions.

Optional AFF and Multi-Channel Tray provide a handy method to convert physical originals into digital files. The benefits are two-fold – considerable time-saving in maintenance and a huge reduction in storage space. It’s safe to say that the NDT-2000 is redefining the NDT/RT landscape.

4. The Many Merits of High-Resolution Imaging

One of the standout features of the NDT-2000 X-ray Film Digitizer is its high-resolution scanning. With an impressive 1200 dpi resolution, this device complies with the ISO 14096 DS 10.0 standard. This level of detail is essential for identifying minute defects that could otherwise go unnoticed.

An integrated green LED further enhances the image-capturing efficiency. This powerful combination results in clear, crisp images that meet the NDT/RT industry’s stringent image quality requirements. In essence, the NDT-2000 ensures no detail is too small to escape attention.

Moreover, high-resolution imaging isn’t merely a luxury, but a necessity in today’s competitive landscape. The ability to capture intricate details can make a significant difference in the overall success of an NDT/RT operation. It’s safe to say that high-resolution imaging is the future of the industry.

5. The Edge of Optional Accessories

The NDT-2000 X-ray Film Digitizer offers more than just exceptional imaging capabilities. It comes with optional AFF and multi-channel trays that enhance working efficiency. These additions prove instrumental in digitizing physical originals for electronic data storage.

Digitization brings about considerable advantages, notably time and space savings. No more shuffling through physical archives or dealing with degraded film quality over time. You can swiftly access, manage, and archive digital files in a fraction of the space.

Ultimately, these optional accessories contribute to a more streamlined, efficient, and organized work environment. By integrating these tools into your NDT/RT operations, you can bring about a remarkable increase in productivity and cost-effectiveness.

6. Exploring the NDT-2000’s Maximum Scanning Capabilities

The NDT-2000 shines when it comes to scanning capabilities. Its maximum scanning area measures up to an impressive 14”x200”, accommodating most sizes of industrial films. This flexibility ensures that the NDT-2000 can cater to a wide range of NDT/RT needs.

The device comes bundled with MiiNDT, a powerful image management software. This software provides multi-functional capabilities such as file building, searching, measuring, annotating, zooming, report making, saving, and burning. These features are designed to make the operator’s job simpler and more efficient.

In conclusion, the expansive scanning capabilities and robust software functionality of the NDT-2000 make it an unbeatable tool. It not only supports a comprehensive range of film sizes but also equips users with advanced software tools to manage these digitized images effectively.

7. Embracing the Spectrum of Image Formats

The NDT-2000 is a versatile device, supporting an array of image formats including DCM, BMP, JPEG, and TIF. The system also supports both lossy and lossless compression formats of JPEG 2000. This flexibility is pivotal for adapting to various image management needs.

With such a wide range of format support, you’re not confined to a specific format or compression type. You can choose the most suitable format based on your specific requirements, be it preserving image quality or saving storage space.

In a world where digitization is rapidly becoming the norm, such versatility is invaluable. The ability to accommodate different image formats means that the NDT-2000 can easily fit into any workflow. It’s just one more way the device caters to the ever-evolving needs of the NDT/RT industry.

8. Experience Gradational Image Layers Like Never Before

The NDT-2000 excels at creating gradational image layers. Thanks to specialized hardware technology, the system can significantly reduce noise ratio. The result is vivid image layers that provide a richer, more detailed view of the subject.

This device does more than just capture images; it brings them to life. Each layer can reveal new information, offering a deeper understanding of the inspected object. This level of detail is critical in industries where detecting even the smallest anomalies can have significant implications.

In essence, the NDT-2000 doesn’t just meet the high standards of image quality in the NDT/RT industry – it raises the bar. It takes imaging from being a mere process to an art form, paving the way for unprecedented detail and precision.

Industrial Film Digitizing System with 1200 dpi High Resolution CCD Image Sensor digitizer with with Green LED Lamp

9. Harnessing the Power of an Intuitive Interface

The NDT-2000 boasts MiiNDT, a user-friendly film digitizing and management software. Its intuitive interface allows you to capture digital images in seconds and provides you with detailed information about inspected images. This software is the perfect companion for your NDT/RT operations.

In addition to digitizing films, MiiNDT comes packed with a multitudeof features such as image enhancement tools, measurement tools, and robust search capabilities. The software simplifies the management and analysis of digital images, freeing you to focus on more critical aspects of your work.

Furthermore, MiiNDT reduces the learning curve associated with new software, ensuring a smooth transition from traditional methods to digitization. It’s clear that MiiNDT, coupled with the NDT-2000, can significantly streamline NDT/RT operations, making them more efficient and less time-consuming.

10. Microtek NDT-2000: A Transformation in NDT/RT Operations

The Microtek NDT-2000 Film Digitizing System is much more than a technological upgrade; it’s a transformation. It empowers businesses in the NDT/RT industry to step confidently into the digital age, making high-resolution imaging and efficient digitization easily accessible.

It’s not just about technology for the sake of technology. It’s about providing practical, down-to-earth solutions to real-world challenges. With the NDT-2000, you can attain quality, efficiency, and ease of use – all in one package.

Ultimately, the NDT-2000 is redefining the standards for the NDT/RT industry. With this device at your disposal, you’re not just keeping up with the times; you’re staying one step ahead. It’s time to embrace the digital revolution and unlock the untapped potential in your NDT/RT operations.

The Impact of the X-ray Film Digitizer on Non-Destructive Testing

The X-ray film digitizer’s introduction has revolutionized non-destructive testing (NDT). Previously, professionals faced challenges in storage, accessibility, and film degradation. However, digitization has mitigated these issues, streamlining NDT processes.

Furthermore, the X-ray film digitizer ensures precision and consistency in testing. By digitizing films, professionals can analyze images more accurately, identify defects with ease, and maintain impeccable quality standards. Therefore, the digitizer has become an indispensable tool in the NDT industry.

Lastly, by transitioning from physical films to digital images, the NDT industry can enjoy sustainable practices. Digital storage reduces physical space requirements, minimizes waste, and lowers the industry’s environmental footprint. Consequently, the X-ray film digitizer’s impact extends beyond operational efficiency to encompass sustainability.

Preparing for the Future with the X-ray Film Digitizer

As we look towards the future, the role of the X-ray film digitizer will only grow more crucial. With advancements in technology, we can expect digitizers to become more sophisticated, offering enhanced features and capabilities.

The digitizer’s adaptability makes it a worthy investment. It can accommodate advancements in imaging technology and software, ensuring you stay ahead in the field of radiographic testing. Therefore, an X-ray film digitizer is not just a tool for today, but a step into the future.

Furthermore, the digitizer facilitates the transition to a paperless environment. This aligns with the growing trend of digital transformation across industries. Thus, the X-ray film digitizer represents a vital link to a more sustainable and efficient future.

Contact ABTec Solutions today on Toll Free (800) 775.8993 or reach out and fill the form and we will contact you as soon as possible.